Trendaavat aiheet

#

Bonk Eco continues to show strength amid $USELESS rally

#

Pump.fun to raise $1B token sale, traders speculating on airdrop

#

Boop.Fun leading the way with a new launchpad on Solana.

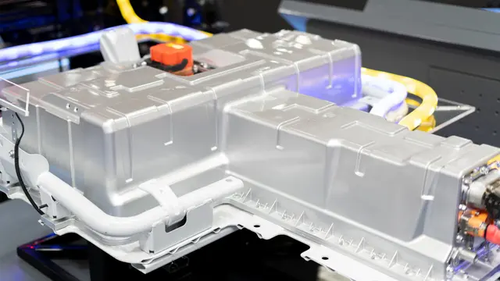

Self-repairing batteries could double EV power packs’ lifespan, performance | Aman Tripathi, Interesting Engineering

The PHOENIX system employs sensors to detect physical swelling, generate internal heat maps, and identify specific gases.

Scientists are developing self-healing batteries designed to diagnose internal damage and initiate repairs, a technology that could double the lifespan of electric vehicles (EVs). The research addresses battery degradation, a key factor limiting EV longevity and adoption.

“Extending battery life will also reduce the carbon footprint of EVs, offering a win-win for both consumers and the environment,” said the researchers in a press release.

This work is part of the EU-funded PHOENIX initiative. The project aims to create durable and sustainable batteries to support the transport sector’s shift toward mandates like the European Union’s 2035 zero-emission goal for new cars.

“The idea is to increase battery lifetime and reduce its carbon footprint because the same battery can repair itself so that fewer resources are needed overall,” stated Johannes Ziegler, a materials scientist at Germany’s Fraunhofer Institute for Silicate Research ISC.

Using sensors to flag defects

The PHOENIX project, a collaboration involving scientists from Switzerland, Germany, Belgium, Spain, and Italy, is engineering a system of internal sensors. This system provides more detailed data than current Battery Management Systems (BMS), which largely monitor basic safety parameters.

“Currently, what is sensed is very limited in general temperature, voltage and current,” noted Yves Stauffer, an engineer at the Swiss Centre for Electronics and Microtechnology (CSEM).

“In addition to providing an estimation of the remaining energy availability, it ensures safety.”

The PHOENIX system uses sensors to detect physical swelling, generate internal heat maps, and identify specific gases, providing an early warning of battery damage.

“When the battery’s brain decides repair is needed, healing is activated. This could mean squeezing the battery back into shape, for example, or applying targeted heat to trigger self-repair mechanisms inside,” explained the press release.

The researchers are exploring several methods, including applying targeted heat to reform chemical bonds.

“The idea is that under thermal treatment, some unique chemical bonding will bounce back,” explained Liu Sufu, a battery chemist at CSEM.

Another technique uses magnetic fields to break down “dendrites,” metallic growths that can cause short circuits.

Improving battery performance too

The research reached a milestone in March 2025, when a new batch of sensor and trigger prototypes was sent to partners for testing on battery pouch cells. This phase will help validate the technology’s effectiveness.

Beyond extending life, the project also aims to improve performance.

“We’re trying to develop next-generation batteries with higher energy density,” Sufu added. The team is testing the use of silicon in battery anodes, which can store more energy than the standard graphite.

The project’s self-healing technology could provide the stability needed to make silicon-based anodes commercially viable, potentially leading to lighter EVs with a longer range.

The initiative addresses the growing demand for EVs and could reduce the industry’s reliance on critical raw materials such as lithium and nickel. The researchers acknowledge that the sensors add to production costs and are working to optimize the technology for economic feasibility.

32,62K

Johtavat

Rankkaus

Suosikit